Sustainable Environment

Sustainable Management Policy

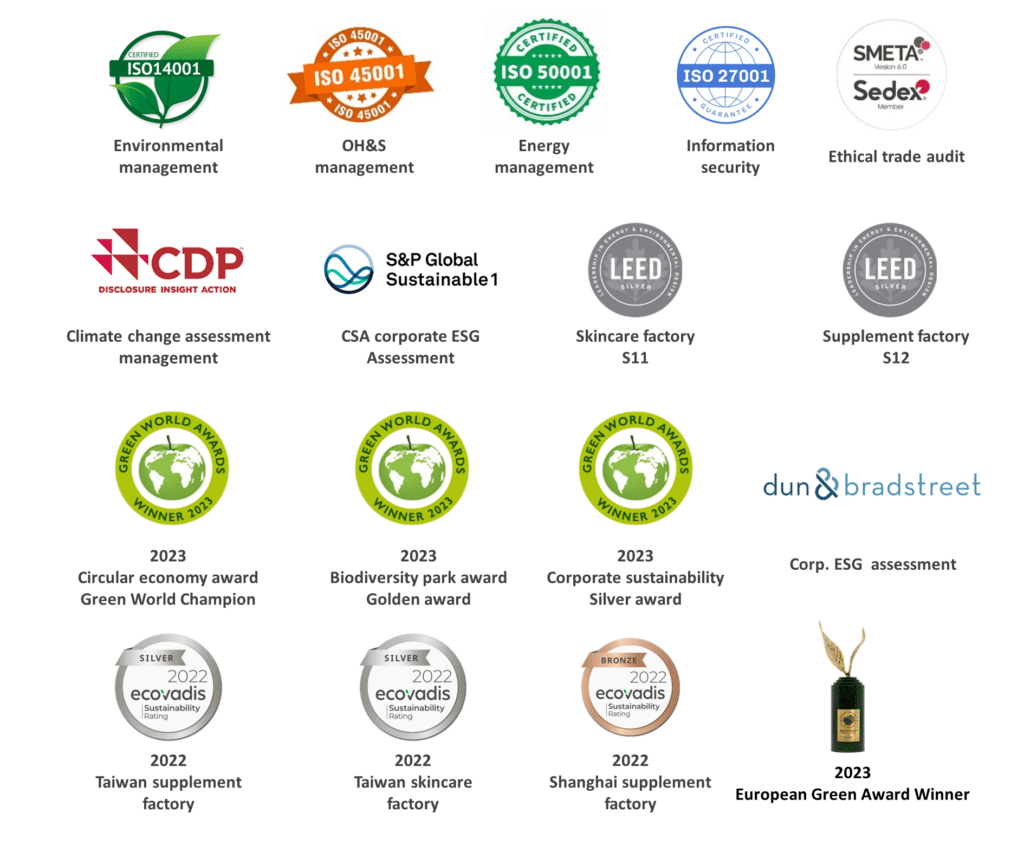

TCI's S factory stands for Safety, Standard, and Speed. Taiwan's Rock Park has passed GMP, GMPC, FSSC22000, SQF (Safe Quality Food), HACCP, ISO 9001, ISO 17025, ISO22000, ISO 22716, and ISO 14001 Environmental Management System, ISO 50001 Energy Management System, OHSAS 18001 and ISO 45001 Occupational Health and Safety Management Systems, BRC (British Retail Consortium) and, the rare US NSF (National Sanitation Foundation) and Australia's TGA (Therapeutic Goods Administration) certification, and the annual EcoVadis Corporate Social Responsibility Assessment. TCI can also assist customers in FDA registration, China food listing permit, Indonesia BPOM application registration, HALAL certification application, including MUI, JAKIM, THIDA and other HALAL types. Thus, allows customers to focus on marketing without worrying about the rapid expansion of the market and the regulatory and qualification requirements of each regional market.

Factory Resource Management Policy

Resource Conservation Awareness Training

In response to the global challenges posed by climate change, TCI upholds the principle of sustainable development by adopting a three-step approach to resource management and utilization: conservation, efficiency improvement, and recycling. We are committed not only to conserving resources during the production process but also to promoting resource conservation and environmental protection awareness across all internal departments. We provide relevant training programs to encourage and enable all employees to participate and implement these initiatives.

Conflict Minerals Sourcing Policy

TCI established conflict minerals sourcing policy and collaborated with the supply chain to only purchase responsible mineral sources for environmental and social issues. Tantalum, Tin, Tungsten, and Gold (3TG) are listed as minerals regulated by the U.S. Conflict Minerals Act, which originated from human rights violations in mining activities in the Democratic Republic of the Congo (DRC).

TCI applied the OECD-aligned mechanism to enhance the due diligence, continued to work with the suppliers through regular meetings and investigations, and ensure to support the use of legal and conflict-free minerals.

Hazardous Substance and Energy Management Policy

Targeting Pollution Prevention

TCI formulated an environmental health and safety management policy and promoted various related management measures with this goal in mind. In addition, TCI conducts internal and external audits and third-party verifications annually to ensure compliance with ISO 9001 Quality Management System; ISO 14001 Environmental Management System; ISO 50001 Energy Management System; ISO 14064-1 Greenhouse gases Part 1:Specification with guidance; PAS2060 Specification for the Demonstration of Carbon Neutrality; OHSAS 18001 Occupational Health and Safety System (in line with the international standard correction TCI adopted the new version of ISO 45001 in 2020); and related environmental regulations. TCI complies with the Waste Disposal Act, Resource Recycling Act, Air Pollution Control Act, Noise Control Act, and Water Pollution Control Act.

In 2023, TCI did not receive any warnings or fines from relevant government agencies for violating corporate governance, labor, environmental protection, quality, or safety regulations. There were also no occurrences of executives violating insider trading laws or receiving customer complaints regarding privacy infringements.

Air Quality

In order to maintain the air quality and the safety of the employees in each factory, TCI plants are equipped with ventilated enclosures that operate around the clock. Operations that may produce odors must be performed in the enclosures to prevent the tests from influencing indoor air quality. The ventilation capacity of the enclosures is regularly tested by a specialized unit to ensure their functionality. In addition, waste gases discharged by the containers are collected in independent pipes and filtered through activated carbon before discharge. The filtration system is overseen and maintained by a specialized unit to ensure that the quality of the waste gases meets the quality standards. In regards to air pollution, no volatile organic compounds (VOC) are produced at TCI’s production premises. Trace amounts of nitrogen oxides (NOx) and sulfur oxides (SOx) come from testing the plant generator, emergency use, fire pumps, stackers and vehicles that use diesel, natural gas combustion of gas boilers, etc. Therefore, TCI regularly reviews existing facilities and manufacturing processes for recruitment that processes pollutants. In addition, TCI schedules regular inspections of boiler equipment and exhaust pipes to ensure that all emissions are in compliance with laws and regulations.

Waste Management

In terms of waste management, the goal is to increase the recycling rate of processed waste and reduce the amount of waste generated. TCI’s waste disposal complies with related laws and regulations and applications for permits. The declaration of waste quantity is in accordance with the law. In addition, TCI commissions qualified institutions to assist with waste disposal. Regarding waste management, TCI’s principle is “When everyone sorts waste, waste will naturally become less; therefore, no value will become valuable, and valuable will become high value.” TCI strictly examines the qualifications of waste treatment institutions. Other than GPS tracking, TCI also ensures the status of waste disposal.

Noise Control

TCI's self-monitoring mechanisms and third-party organizations provide monitoring reports periodically. Noise levels are within regulatory standards in all office and factory environments, including the headquarters located in Neihu and the Panshi premises.

Water Resource Management

All water sources for TCI's Pingtung Precise iManufacturing Center industrial use are tap water. The approved water consumption is 1200 x (S5 + S9+12) + 300 x (S11) = 1500 CMD. S5 is the Functional Drink Factory, S9 is the Functional Food factory, S11 is the Eco Facial Mask Factory, and S12 is the ASRS Warehouse and office. S11 is designed with rainwater recovery piping for planting and irrigation, and the recovered RO concentrated water is used for toilet flushing. In addition, condensate water recovery is set up in the steam circuit of the PABP factory used for steam boiler water replenishment to improve the efficiency of use. In the future, TCI will continue to plan water conservation measures and recycling programs to manage water resources effectively.

Waste Water Management

The wastewater plant of the Pingtung Agricultural Biotechnology Park Administration treats the wastewater from TCI’s factory. The S5 and S9 functional drink and food factories have separate wastewater treatment facilities. Before discharging to the Pingtung Agricultural Biotechnology Park wastewater treatment plant, the factory initially improves water quality items such as water temperature, pH, suspended solids, chemical oxygen demand, and biochemical oxygen demand. In addition, the Company also commissions an inspection company approved by the Environmental Protection Administration to conduct wastewater quality inspections every six months. The overall wastewater management process ensures that the discharged wastewater complies with the Water Pollution Control Act and the regulations of the Agricultural Biotechnology Park on water quality standards. No spills, overflows, or water quality violations occurred at the factory in 2023.

Carbon Emissions Management

Since the United Nations Government Panel on Climate Change has identified greenhouse gas emissions as the leading cause of climate change, and its impact is not only a change in the global environment but also an impact on the daily lives and economic activities of human beings around the world, we recognize that carbon emission management and carbon emission information disclosure has also become an important issue in corporate operations. TCI is a "committed" participant in actions to reduce carbon emissions in alignment with scientific goals. It has become the first biotechnology company in Asia and Taiwan to establish carbon reduction targets through SBTi review. The SBTi carbon reduction targets are as follows: Using the baseline year of 2018, TCI commits to reducing the greenhouse gas intensity of Scope 1 and Scope 2 emissions by 51% by the target year 2030, while also reducing Scope 3 emissions by 15%. Furthermore, regarding Scope 3 emission reduction actions, we will gradually require suppliers to provide electricity-related carbon emission data, which will serve as a reference for future Scope 3 carbon emission management. Additionally, a temperature increase control of 1.5°C has been set.

According to Taiwan’s current “Greenhouse Gas Reduction and Management Act,” TCI is not included as a target of greenhouse gas emissions reporting and control. However, as international climate awareness has increased, climate change risk management, greenhouse gas management, and greenhouse gas emissions information disclosure have become important issues in corporate operation management. Since 2018, TCI has conducted annual greenhouse gas inventories according to the GHG Protocol in the Pingtung Rock Park, including direct emissions (Scope 1) and indirect emissions (Scope 2), and obtained ISO 14064-1 third-party verification.In 2023, Pingtung Rock Park's direct emissions amounted to 3,646 tCO2e, and indirect energy emissions amounted to 9,669 tCO2e.

International Sustainability Initiative

TCI maintains its focus on international sustainability issues and trends. The Company commits to ambitious sustainability goals by publicly responding to international initiatives. TCI continues to invest in the Company’s sustainability transition and hopes to make an impact in the industry value chain. The Company has already committed itself to a landmark initiative in energy and climate change and is actively involved in renewable energy development and energy reduction. In 2021, TCI’s Science Based Target (SBT) formally passes the audit, becoming a select few Taiwanese companies to have passed the audit.

| Initiative Name |

Member Since |

Content | TCI’s Commitment |

| RE100 | 2018 | Affected companies must commit to using 100% renewable energy by 2050 | 100% use of renewable energy by 2030 |

| EP100 | 2019 | Affected companies must set targets for improving energy productivity or integrate energy management systems |

Integration of energy management system by 2026. Using 2016 as the base year, energy productivity will increase by 35% in 2040 |

| SBTi | 2021 | Commitment to corporate carbon reduction targets based on a rigorous methodology developed by the Science-Based Target Reduction Initiative (SBTi) | Using 2018 as the base year, decrease the absolute emission reduction of Scope 1 and 2 by 51% and decrease the emission of “purchase of goods and services” of Scope 3 by 15% by 2030. |

| Alliance for Water Stewardship, AWS | 2022 | Improving the sustainable management of water resources: implementing internal (organizational) and external (watershed) measures to maximize the water resource benefits for society, the environment, and the economy. | The first Taiwanese company has been granted permission to join the Alliance for Water Stewardship (AWS), an international organization for water resource management. |

*EP100 Energy Productivity Unit: Revenue/kWh

Achievements

TCI's Pingtung Rock Park obtained the SGS Verification Statement per the 14064-1 inspection criteria. The CO2 equivalent in 2020 is 15,123.214 metric tons of CO2 equivalent.

(1) Solar Panel Constructions

TCI installed solar power generation equipment on the rooftop of the Pingtung Precise iManufacturing Center (Rock Park) and Shanghai Precise iManufacturing Center (Golden Hill Park). Pingtung Precise iManufacturing Center’s total installed capacity is1,362kW, with an installed area of 7,940 square meters. Shanghai Precise iManufacturing Center’s total installed capacity is 689 kW, with an installed area of 7,500 square meters. The roof of the S12 automated warehouse, completed in 2019, is also equipped with solar panels with a capacity of 400kW to produce green electricity for the warehouse's use. Thus, reducing greenhouse gas emissions by approximately 886 metric tons of carbon dioxide equivalent (CO2e) compared to a non-solar photovoltaic system. Considering the limited roof area of the factory, to achieve the goal of RE100 energy transition, TCI now proactively looks for space outside the factory to invest in renewable energy construction and expects to achieve 50% green electricity use by 2025 and 100% renewable energy use by 2030.

(2) Energy Management

TCI's Pingtung Rock Park fully implemented the ISO 50001 energy management system and installed a solar power system on all roofs. The S11 Eco Facial Mask Factory and S12 ASRS warehouse obtained the U.S. LEED green building certification from the U.S. Green Building Council (USGBC), fully committed to reducing energy consumption and greenhouse gas emissions. In 2022, tthe PABP factory conducted various power-saving projects such as air conditioning fan setting scheduling control, steam cascade between factories, and APP-controlled process equipment shutdown confirmation, which are expected to achieve an energy efficiency improvement of 38%.

Energy Efficiency Awareness Training

In 2023, we conducted a series of energy efficiency training sessions and energy-saving strategy workshops, focusing on enhancing employees' awareness and capabilities in energy management. These workshops were held irregularly and were attended by employees from various departments, such as factory operations and IT departments. Through cross-departmental collaboration, we explored energy-saving strategies in depth. We invited external experts to introduce energy management systems, helping employees understand how to use these systems more effectively to manage and monitor energy usage. By combining external resources with the expertise of internal staff, we jointly developed the company's energy-saving plans and continuously reinforced employees' awareness and practices in energy transition and efficiency improvement through training.

(3) Afforestation Adoption

Recognizing the importance of biodiversity conservation and zero deforestation, we are committed to developing and implementing Group-level best practices for biodiversity conservation and zero deforestation in conjunction with our operations and key value chains, with a target year of 2025. The Company pledges not to conduct operations, sales, or other business activities at or near sites of national biodiversity importance to fulfill our commitment to biodiversity and zero deforestation. In addition, we require upstream and downstream key value chain/supplier partners associated with the operations of the TCI Group to endorse and jointly comply. This declaration covers the Sustainable Development Goals (SDGs): SDG 7 Affordable and Clean Energy; SDG 9 Industry Innovation and Infrastructure; SDG 12 Responsible Consumption and Production; SDG 15 Life on Land; and SDG 17 Partnerships for the Goals.

(4) Zero Deforestation

In May 2017, TCI signed an agreement with the Forestry Bureau of the Council of Agriculture, Executive Yuan, Taiwan, to adopt 17.25 hectares of land for afforestation. The afforestation work was launched in July, 2017 and has reduced CO2 emissions by 225,720 kg so far.

(5) Organizational Greenhouse Gas Verification Certificate

TCI in Pingtung Rock Factory has obtained the SGS certification statement based on the 14064-1 inspection standard. In 2023, the carbon dioxide equivalent was 13,314 tCO2e.

Factory Resource Management Data

Waste Management (tons)

Rock Factory

| 2020 | 2021 | 2022 | 2023 | |

| Industrial Waste | 1,460.2 | 1098.3 | 1123 | 1810 |

| Hazardous Industrial Waste | 1.1 | 0.6 | 0.675 | 0 |

| Total | 1,461.3 | 1098.9 | 1123.6 | 1810 |

Water Resource Management(tons)

| 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | |

| Water withdrawal | 208,939 | 297,939 | 322,164 | 354,202 | 346,154 | 324,405 |

|

Water Intensity (tons/US$Million revenue) |

1,237 | 1,452 | 1,570 | 1,734 | 2,075 | 1,573 |

Air Pollution Control (tons)

| 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | |

| NOx | 1.61 | 2.37 | 3.47 | 3.70 | 5.42 | 3.86 |

| SOx | 0 | 0 | 0 | 0 | 0 | 0 |

Greenhouse Gas Emission Intensity (tCo2e)

| 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | |

| Direct emission (Scope1) | 2,540 | 3,800 | 4,917 | 4,296 | 3,723 | 3,645 |

| Indirect emission (Scope2) | 6,051 | 8,021 | 10,205 | 100,683 | 9,954 | 9,669 |

| Total | 8,591 | 11,821 | 15,122 | 14,979 | 13,677 | 13,314 |

| Emission intensity (tCO2e/US$Million revenue) | 51 | 58 | 74 | 73 | 82 | 83 |

| Coverage (%) | 40 | 40 | 40 | 40 | 40 | 40 |

Note: The greenhouse gas emission data only covers the Pingtung Rock Park.

2019 GHG inventory audit certificate

2020 GHG inventory audit certificate

2021 GHG inventory audit certificate

2022 GHG inventory audit certificate

2023 GHG inventory audit certificate

Green Products and Manufacturing

SR5C Sustainable Packaging Solution

At TCI, our commitment to sustainability is at the forefront of our innovation and product development. To strengthen this commitment, we are proud to introduce SR5C, our strategic approach to advancing sustainable packaging practices from 2025 to 2030. SR5C focuses on five core pillars: Reduce, Reuse, Recycle, Replace, and Retain, all working together to create eco-friendly packaging solutions that align with environmental responsibility and regulatory standards.

- Reduce: Minimize packaging and reduce the use of printing ink.

- Reuse: Increase the proportion of recycled materials and acquire sustainability and environmental management certifications

- Recycle: Introduce mono-material facial masks and sachets to enhance recyclability.

The strategy will support TCI's sustainability commitment by reducing the weight of packaging to minimize transportation costs and carbon footprint, increasing the use of recycled materials, and ensuring that our packaging integrates seamlessly into current recycling systems. We are also committed to replacing traditional materials with sustainable alternatives, such as higher paper content and reduced ink usage, to lessen environmental impact while maintaining product integrity. Additionally, we retain product safety and quality through rigorous testing and compliance with global regulations.

SR5C is more than just a strategy; it is our pathway to meeting the needs of our clients, the environment, and future generations through sustainable, responsible business practices.

Bestowing Value on Agricultural By-Product

TCI recognizes that approximately one-third of global food production is lost or wasted. Hence, losses and waste are prevalent at any point between the production and consumption of food, regardless of location. To collaboratively reduce waste with the rest of the world, TCI responds to the global target of reducing food loss and waste by 50% by 2030. Since 2021, TCI worked together with Taiwanese farmers to develop innovative and collaborative methods to prevent waste. The Company purchases subpar fruits or agricultural wastes from farmers, increasing farmers' additional income and transforming these original waste materials into highly valuable healthcare products, skincare items, and packaging materials.

For example, TCI utilizes banana peels and stems to create 100% biodegradable face masks, and mix Djulis husks with biodegradable PBS to manufacture containers for Djulis cream. These containers consist of caps, inner boxes, and outer boxes. Caps and outer boxes are made from recycled plastic (PCR), while inner boxes are crafted from Djulis husks. After using the lotion, consumers only need to purchase the inner box. If this production model sells 100,000 units annually, with 50,000 units being inner boxes, it is estimated to reduce 14,286 kgCO2e, which is roughly equivalent to the carbon sequestration capacity of 1,190 trees.

TCI dedicates to developing agricultural waste into high-value products, helping consumers prevent food loss and waste, and responding to the global objective of reducing food loss and waste by 50% by 2030.

"Upcycle Agricultural Waste to Gold": Leverage biotechnology to create diversified health products.

-

Mitigating food loss: Taiwan produces 4-5 million tons of agricultural waste each year, and the disposal process produces methane with high greenhouse gas potential, but most farmers cannot afford to dispose of this waste, and about 30% of the food ends up in landfills and 50% in compost.

-

Reducing greenhouse gas emissions: By using natural ingredients to produce health foods and functional beverages, TCI believes it has a responsibility to change the linear economic model, mitigate carbon emissions from food loss, and further create sustainable financial and non-financial value for local farmers, international customers, and global consumers, joining and delighting the lives of consumers.

- Becoming a creator of high economic value: Granting new economic value to agricultural by-product in Taiwan, while reducing the use of raw materials. Moving forward with an upcycling mindset and, through this approach to generating more market value for brandedcustomers.

In 2015, TCI launched the "Turning Agriculture Waste to Gold" Circular Economy Project (the "Project"), which integrates big data, artificial intelligence, and automated laboratories through their proprietary "bio-resource data mining platform." Thus, speeding up the development of effective ingredients and reducing the time required for the original 17,000 experiments by 70 times. Following the upcycle concept, the project includes raw material development, efficacy analysis, local agricultural products/raw materials procurement, product formula design, standardized manufacturing process, product packaging, and marketing business. TCI transforms agricultural wastes initially classified as "plant-based waste" into health product raw materials and gives them high economic value. The number of patents obtained ranked first in the pharmaceuticals field in Taiwan in 2020 and received recognition from several international invention awards. Since the project launch, nearly 20 items of agricultural waste have been commercialized and applied to 32 healthcare products sold to 63 countries worldwide.

Fair Trade and Sustainable Farming

As a sourcing company for healthcare raw materials, TCI commits to controlling the sustainability of raw material production. The coffee beans and West Indian cherries that the Company purchases are traded fairly, and promise small farmers a guaranteed purchase price to maintain their livelihood and sustainable operation, preventing them from being exploited by traders or having their livelihood affected by drastic price fluctuations. Fair-trade crops are often produced using nature-friendly farming practices that respect nature. Adopting friendly farming practices is a good way to treat the land and sustain the environment, but it also comes at a higher cost. This is the biggest obstacle for many farmers when they abandon their farming practices. TCI provides technology and resources for farmers' transformation, helps introduce friendly farming and regenerative farming, and provides guaranteed purchase prices to establish long-term partnerships with farmers to jointly practice environmental and social sustainability.

Example of Agricultural By-products: Lyophilized Mask

TCI utilizes freeze-drying technology to lock the essence of ingredients extracted from agricultural by-products into the natural fiber cloth and package the finished product in a recyclable paper bag, reducing the weight of the physical product by more than 20g, which dramatically reduces our transportation carbon emissions, and is environmentally friendly from the source to end consumer. The dry mask emphasizes environmental protection from the inside out. The cloth is made of 100% natural fibers, and the inner material is made of special TCI extracts, such as Taiwan's unique red quinoa, pineapple peels, and discarded ponkan unripe fruit, extracting the efficacy ingredients from original waste products, and utilizing freeze-drying technology for the cloth mask to carry concentrated essences. The addition of highly concentrated human-like collagen is the finishing touch. We package the prepared product into a recyclable paper bag. The user can apply the mask using the remaining water on their hands and face after showering or washing their face. It can also be used with commercially available mineral water, requiring only around 10g for a convenient experience. Users can insert the final packaging into magazines for recycling.

Practicing Sustainability Commitment Through Product Packaging

In terms of product packaging, TCI invested in digital printing, which is more energy-efficient and carbon-reducing than traditional printing. With the "trackable marketing technology" and platform, customers can conduct marketing activities, such as raffles and gift sending, and discount coupons, after adopting the "trackable marketing technology" platform (i.e., each product has a unique barcode). In China, for example, marketing campaigns are paperless, reduce cross-city movement and significantly increase customer engagement rates.

In addition, the Company made efforts in the labeling of drink bottles. Traditional collagen drinks use 106mm*64mm bottle labels. However, we reduced them to 55mm*35mm, and the new carbon reduction labels are estimated to emit 212.76 kg CO2e per 100,000 labels, a reduction of 71% in carbon emissions compared to traditional bottle labels.

In selecting packaging materials, TCI adheres to environmental sustainability and works with packaging material manufacturers to influence international customers to purchase FSC-certified paper for product packaging. In terms of the final product, TCI started designing waterless facial masks for customers to reduce the packaging and carbon footprint of the product during delivery. In addition, in 2021, the Company assisted Chinese customers in obtaining the carbon neutral certification for their health drink products, the first zero carbon product in China certified by PAS 2060 standard and verified by the third-party CQC China Quality Center. TCI expects to achieve a green design concept for 30% of its products by 2025.

Exceeding Standards, Committed to Not Use Harmful Substances

As a purchaser of health supplement ingredients, TCI is committed to controlling the sustainability of raw material production. The highest criterion for raw materials are not harming human health and being environmentally friendly. Raw material suppliers are required to submit relevant certificates, and raw materials undergo standardized acceptance procedures, including specification and quality testing. Inspection standards also reference the latest international trends and prioritize surpassing regulations from various countries, such as the US FDA, Canada CFIA, UK FSA, Germany BVL, France ANSES, Australia TGA, among others, or based on customer requirements. All products are regulated, conforming to or exceeding EU REACH standards. The raw materials used in products are committed to not containing the EU REACH SVHC highly concerning substances (accumulating 233 items) to ensure their safety.

Biodiversity Park

In 2021, TCI and the National Pingtung University of Science and Technology cooperated to complete the first biodiversity park in Taiwan, which includes plant rehabilitation, habitat creation, cultivation and production of functional crops, and low-carbon farming trials. In the future, it is expected that the methodology and experience gained from the Park will be applied to all the farmers who work with TCI to create a 1,000-hectare "Sunrises Farm" in Taiwan.

The Park plans to restore a variety of Taiwan's native plants, such as Protea, white Hibiscus sabdariffa, Chiapao melon, daylily flower, and white wax apple, through environmentally friendly farming methods and planting. For example, the Park cooperates with the Department of Forestry of the National Pingtung University of Science and Technology and the Graduate Institute of Bioresources to conduct regular surveys on soil carbon sinks and species changes in the Park and research how to increase soil carbon sequestration capacity and field biodiversity, to create "ecological prosperity" and protect the biodiversity of the land.

Through plant restoration, not only can we protect more plant species, but we can also find out the health and economic value of native plants through TCI’s “Bio-Resource Data Mining Platform” and create industrial wealth through plant restoration. At the same time, TCI and the National Pingtung University of Science and Technology conducted the “Rehabilitation Internship” program, leading students to practice the cultivation and production of functional biomedical crops in the Biodiversity Campus to realize “future prosperity.”

-

Ecological Prosperity: restore Taiwan's native or rare plants, seed rescue, create and enhance biodiversity, and experiment with low-carbon farming methods to improve soil carbon sequestration benefits.

-

Industrial Prosperity: Introduce environmentally friendly farming methods to create economic benefits for farmers. Develop and manufacture natural health care products and skin care products to benefit customers economically.

- Future prosperity: Cultivate prospective skilled personnel and realize a future of social prosperity.

Starting from May 2022, TCI in collaboration with the Departmentof Forest of National Pingtung University of Science and Technology, initiated a one-year "Biodiversity Survey Project" in the Biodiversity Park. A total of 72 families and 214 species of plants were recorded, with native Taiwanese plants accounting for 46.26%. There are 7 species of plants that are unique to Taiwan: Machiluskusanoi, Machiluszuihoensis Hayata var. zuihoensis., Syzygiumformosanum, Koelreuteria elegans, Acer cinnamomifolium, Dendrocnidemeyeniana, and Chenopodium formosanum.

In the animal species survey, 203 species were recorded, including 7 species that are unique to Taiwan: Diplodermaswinhonis, Dendrocittaformosaeformosae, Psilopogonnuchalis, Paraglenurusriparius, Lethe mataja, Adoretusformosanus, Hexacentrusformosanus.There are also 8 subspecies of animals unique to Taiwan: Callosciuruserythraeusthaiwanensis, Caprimulgus affinisstictomus, Hypothymisazureaoberholseri, Oriolustrailliiardens, Pycnonotus sinensis formosae, Otus lettiaglabripe, Amida tricolor formosana, and Histiaflabellicornis ultima.

TCI has collaborated with the World Vegetable Center on a "Seed Revitalization Project". The results have yielded 3 species and 10 strains, including Coccinia grandis, Hibiscus sabdariffa, and Glycine soja, all of which are plant species unique to Taiwan. In the future, TCI will continue to obtain 30 types of seeds annually from the World Vegetable Center for seed preservation. This effort aims to mitigate the environmental impacts that Taiwan's agriculture might face in the future. Through this project, Taiwan's unique plant species can be preserved internationally, and based on research findings, they can offer enhanced nutritional value.

River Basin Recovery

TCI: Nurturing Nature Today, Cultivating Hope for Tomorrow

A Promise to Return to Nature

In the rush of modern agricultural expansion, the delicate balance of our land’s ecosystems is under unprecedented strain. TCI understands the urgent need to restore this balance, and so we have launched the River Basin Recovery Initiative. Rooted in pesticide-free, eco-friendly agriculture and the restoration of watershed environments, this initiative is designed to rebuild ecosystems sustainably. Our vision is to create a pristine eco-village, a place where rivers, forests, and fields are reawakened, radiating life anew, as we strive to protect Taiwan’s cherished natural heritage.

Restoration Actions and Our Vision for the Watershed

This is more than a project; it is our heartfelt commitment to the land. Together with local farmers, we are building a pure, unpolluted eco-village. Our goal is for the watershed to become a thriving sanctuary of biodiversity, where people and nature can coexist in harmony. We dream of clear streams flowing again, of every inch of land bursting with life, embodying our promise to the earth and our pledge to the sustainable revival of this precious landscape.

Eco-Friendly Agriculture in Harmony with Local Culture

1. Taiwan Blue Magpie Tea: Cultivated with Care

We support local tea farmers in adopting non-toxic, environmentally friendly practices in cultivating Taiwan Blue Magpie Tea within the Feitsui Reservoir watershed. Every leaf is rigorously tested to ensure it’s free from pesticide residues. This dedication not only safeguards the habitat for native flora and fauna, like the Taiwan blue magpie, but also enriches soil health, revitalizes the local economy, and lays a strong foundation for sustainable development.

2. Red Quinoa Cultivation: A Bond Between Indigenous Culture and Nature

In Maijia Township, Pingtung, we lease land to promote pesticide-free red quinoa farming. Known as the "ruby of grains," red quinoa holds deep cultural significance among Taiwan’s indigenous people, carrying generations of tradition and memory. Red quinoa is not merely a food source—it embodies cultural identity and the essence of life itself, weaving together the fabric of local customs and ways of life. Through this cultivation, we aim to preserve the wisdom that indigenous people hold for their land, a legacy passed from one generation to the next. This is more than ecological restoration; it is a celebration of culture and a tribute to the harmony between people and nature.

Our Commitment: Building a Sustainable Legacy for Future Generations

Every stream, every inch of soil, is worth protecting. Every step in the River Basin Recovery Project is a reflection of our unwavering commitment to nature. Our purpose is not only to restore ecological balance but to build a safe, enduring home for generations to come. Through our dedication to this land, we hope to see it flourish, transforming into a living testament to sustainable coexistence—a gift of irreplaceable natural and cultural treasures for the future.

Certification and External Audit

EcoVadis TCI CO LTD PABP BRANCH Silver Certificate

EcoVadis TCI CO LTD BIOCOSME PABP BRANCH Silver Certificate

EcoVadis Shanghai Golden Hill Park Bronze Certificate

LEED Green Building Certificate – S11 Eco Facial Mask Factory

LEED Green Building Certificate – S12 ASRS Warehouse

Pingtung Rock Park Organizational Greenhouse Gas Verification statement

Pingtung Rock Park Validation Opinion Statement of Carbon Neutrality Declaration

Awards