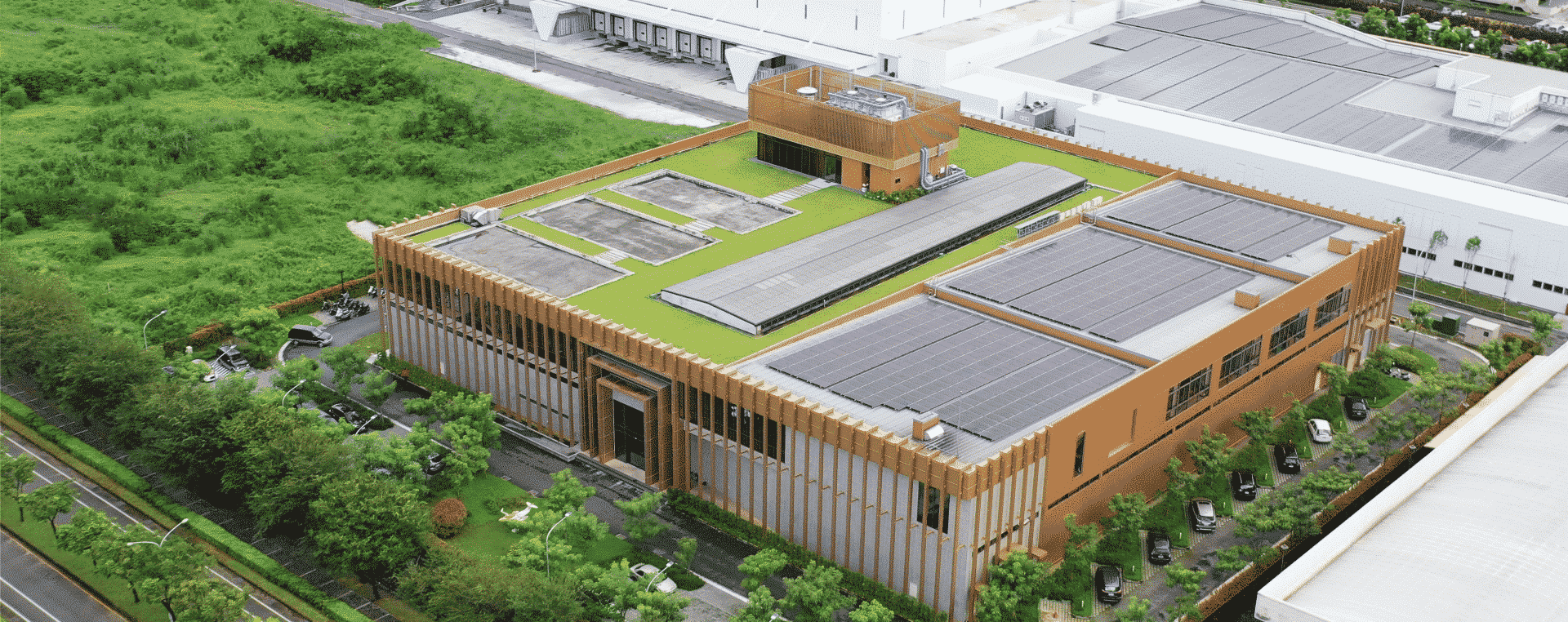

Sustainable Intelligent Factory

World’s highest standards, creating a green supply chain

S5 Taiwan Functional Drink Factory

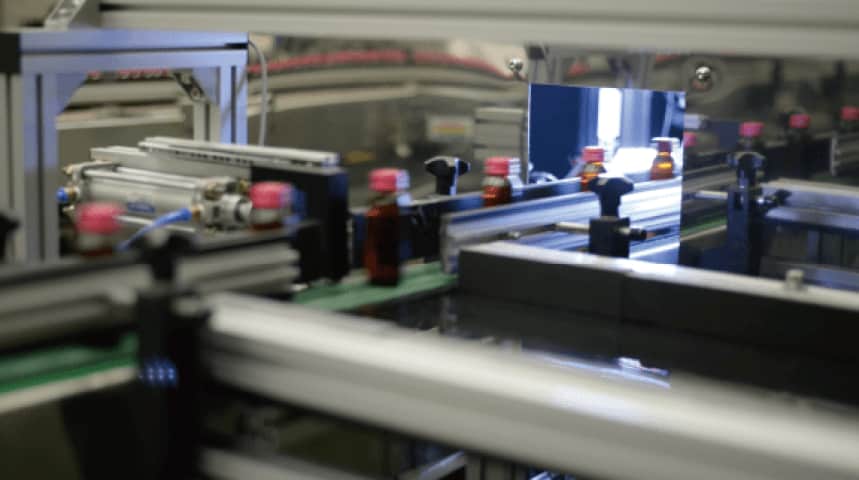

Established in 2011, S5 Taiwan Functional Drink Factory is our first large-scale factory. From mixing of raw ingredients to bottling, labeling, boxing, and packaging, the entire production line is automatic and continuous.

QUALITY IS OUR LEGACY

Production Dosage Form

- Functional drink

- Jelly

- Liquid sachet

Monthly Production Capacity

- Functional drink - 24 million bottles (with Double NUTRI Technology)

- Double NUTRI liquid sachet TDN - 20 million sachets

Special Certifications

- BRC British Retail Consortium

- HALAL Certification

The small capacity and convenient liquid sachet is popular

The brand new Double Nutri liquid sachet production line is 50 times the production speed of traditional machinery. The production line can produce 5mL to 25mL products and can be filled with liquid and granular fillings, coating oil-soluble, water-soluble, and water-insoluble nutrients to achieve the highest bioavailability.

The six-row filling machine splits the aluminum roll into 6 rows, makes the sachet, fills, seals, and then cuts the aluminum roll for filling and production. The sealing can be designed as a small opening, a slanted opening, or a flat opening.

SQF Quality Guarantee is a stepping stone for exporting products to the world

SQF (Safe Quality Food) is globally recognized. Any food produced in the S5 factory can be marked with the SQF certification on the packaging. Only the highest standard SQF Level 3 logo can be used in advertising or on the product packaging. The scope of SQF verification is from farm to table, including “source management, production, processing, preparation, and manufacturing.” In addition to focusing on “food safety,” it is also a product “quality certification” that is different from the past.

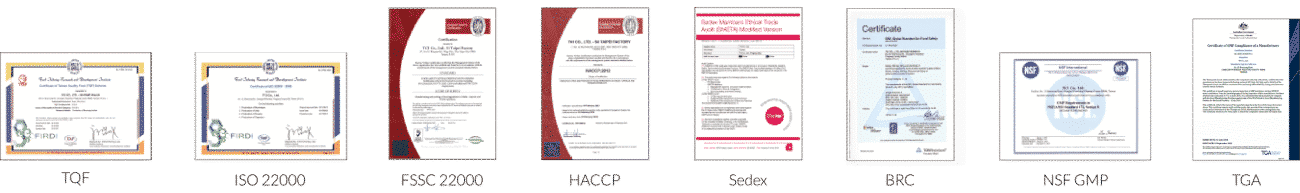

Manufactured by TCI, anywhere can be a sales market

The factory has passed the Taiwan GMP, ISO22000, EU FSSC22000, HACCP, ISO50001 (energy control management), Britain’s Sedex ethics certification, BRC Retailers Association and the rare US NSF GMP. We can assist customers in FDA registration, Chinese food market permit, Indonesian BPOM application registration, HALAL certification application, including MUI, JAKIM, THIDA, etc. Allowing customers to focus more on marketing without worrying about the rapid market expansion and sales in new areas.

Particles smaller than PM 2.5 cannot be allowed

The 50mL functional drink production line utilizes automatic loading and unloading of bottles to reduce personnel contact. The controlled area is a class 100,000 clean-room machine shop and the inside of the filling machine itself is a highly efficient class 100. After the bottles enter the machine, the bottles are turned upside down and flushed with high-pressure pure water. Then, the bottles are emptied and filled with the contents. The automatic cap feeding machine turns the bottle cap upright and sends it to the cap feeding track to seal the bottles.

AI Screening, not allowing any possibility for error

In alignment with our state-of-the-art automated production processes, TCI has made a significant investment in developing the cutting-edge Eagle Eye Monitoring System. This advanced technology, featuring high-speed CCD (Charge-Coupled Device) sensors, enables real-time production safety inspections that exceed human visual capabilities. It identifies defects such as abnormal or deformed bottle caps, thread distortions, cracks, impurities, glass fragments, and performs ultrasonic liquid level assessments. The system automatically rejects non-compliant products and operates continuously, inspecting 16.7 bottles per second with an exceptional detection accuracy of 99.9%, ensuring reliable, around-the-clock quality control.

CERTIFICATIONS

S11 Eco Facial Mask Factory

Established in 2017, the S11 Eco facial mask factory is not only an S-grade factory, it is the world’s first environmentally friendly facial mask factory. Powered by solar energy. with zero carbon footprint emissions, the factory has obtained the green building certification and the US LEED certification. TCI is the only company in Asia that has obtained the ECOCERT COSMOS organic cosmetics certification.

QUALITY IS OUR LEGACY

Production Dosage Form

- Mask

- Bottled skincare

- Tube skincare

Monthly Production Capacity

- Facial/Eye mask - 20 million sheets

- Bottled skincare - 250,000 bottles

- Tube skincare - 550,000 tubes

Special Certifications

- LEED Certification from the United States Green Building Council (USGBC)

- US GMPC

- EU ISO22716

- ISO Certification

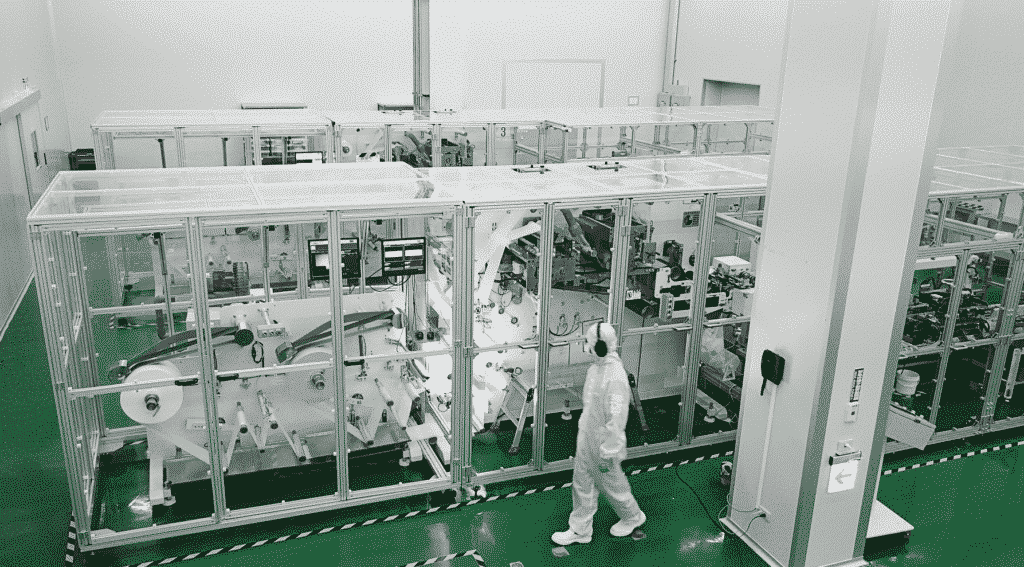

Automatic facial mask production line

From stacking to printing, the facial mask production line operates with automatic machine operation. The condition of the cloth roll is automatically inspected, the screening system ensures that each facial mask has reached the specified weight.

RO Reverse Osmosis

Ultrapure water that has undergone multiple processes is the main material for our production of facial masks.

Soft-water system - active carbon filter - reverse osmosis twice - electrolyte deionization system (EDI) - UV light sterilizer (UV)

*Wate standard for hemodialysis

CERTIFICATIONS

S12 ASRS Warehouse

Established in 2019, the S12 ASRS Warehouse implemented the energy-saving methods of LEED, the US Green Building Council Certification, to make the overall building, energy assessment, and construction more environmentally and ecologically friendly. The S12 factory assembles high-speed automation equipment, smart warehousing, the Schubert automatic packaging machine, and the digital printing factory.

QUALITY IS OUR LEGACY

Smart Warehouse Factory

S12 is a comprehensive logistics centre with 8,238 storage spaces for global delivery and is connected to 3 factories. Implemented into S12 is an automated storage and retrieval system and is equipped with automated guided vehicles and sorting transfer vehicles. The building is designed to withstand level 5 earthquakes and is equipped with temperature and humidity control. The high-speed automatic crane can reach up to a maximum of 200 meters per minute and can quickly deliver and retrieve materials. Connecting the automation from the production line from delivering materials to packaging, operation time and manpower can be reduced by 30%.

Schubert Automatic Packaging Machine

Using the world-renowned packaging machine manufacturer, Schubert, the automatic packaging machine can package using various packaging methods. The automatic packaging machine is connected to the drink line and handles the packaging of 750ml and 50ml bottles. For the 750ml large bottle type, the machine can package 100 bottles per minute. For the 50ml bottle type, the machine can package 400 bottles per minute for 8/10/12 bottles per package. The entire machine is an intelligent modular design, which allows for quickly switching of molds for different packaging box types.

STV Sorting Transfer Vehicle

The maximum speed of the sorting transfer vehicle can reach up to 160 meters per minute, speeding up the transportation of raw materials between factories.

AGV Trackless Automated Guided Vehicles

After the MES production management system issues the order, materials are retrieved from the automatic warehouse, then automatically transported to designated areas with the AGV. With the AGV, transportation in the warehouse is automatic, which maintains a clean factory environment.

Digital Printing

Packaging materials for drinks, powder sachets, liquid pouches, facial masks, etc., produced by TCI can be printed through the IOP integrated solution. The IOP integrated solution connects packaging to the internet, utilizing “changeable packaging design” to increase product competitiveness, and combines “one product, one QR code” to track the product.

CERTIFICATIONS

S9 Taiwan Functional Food Factory

Established in 2015, the S9 Taiwan functional food factory mainly produces solid form dietary supplements including sachet, capsule, tablet, etc. Combined with automatic packaging equipment and automatic transportation system, the process greatly shortens the delivery time.

QUALITY IS OUR LEGACY

Production Dosage Form

- Includes capsule

- Tablet

- Powder sachet

Monthly Production Capacity

- Functional powder sachet - 47 million sachets

- 3-side seal sachet - 11.6 million sachet

- Tablet - 88 million pieces

Special Certifications

- BRC British Retail Consortium

- HALAL Certification

Automatic Pack and Stack Robotic Arm

The advanced spider robotic arm combined with visual recognition, the machine can align and grab incoming materials and automatically place them on the conveyor belt. The system automatically calculates the quantity which greatly improves the accuracy, allowing the production line to grab 200 products per minute and package 40 boxes per minute.

Automatic packaging robotic arm

Using the robotic arm of the internationally famous brand, ABB, and combined with the packing and stacking system, the machine can pack and stack 13 different types of boxes. Along with the visual recognition system, the production line has automated the packaging process to save manpower.

CERTIFICATIONS

S8 Shanghai Dietary Supplements Factory

The S8 Shanghai dietary supplements factory boasts high-speed production and advanced automation, allowing each production line to operate efficiently with just 8 personnel. Additionally, the facility features a high-speed solid supplement production line, making it a key base for TCI’s production of functional drinks and supplements in China.

QUALITY IS OUR LEGACY

Production Dosage Form

- Functional drink

- Functional powder

- Functional sachet

- Functional tablet

- Exclusive Double Nutri liposomal technology

Monthly Production Capacity

- Functional drink - 30 million bottles

- Functional powder sachet - 12 million sachets

- Tablets - 110 million

- Liquid sachet & jelly- 8 million

Special Certification

- MUI Halal Certification

AI Quality Control

In alignment with our state-of-the-art automated production processes, TCI has made a significant investment in developing the cutting-edge Eagle Eye monitoring system. This advanced technology, featuring high-speed CCD (Charge-Coupled Device) sensors, enables real-time production safety inspections that exceed human visual capabilities. It identifies defects such as abnormal or deformed bottle caps, thread distortions, cracks, impurities, glass fragments, and performs ultrasonic liquid level assessments. The system automatically rejects non-compliant products and operates continuously, inspecting 16.7 bottles per second with an exceptional detection accuracy of 99.9%, ensuring reliable, around-the-clock quality control.

CERTIFICATIONS

S16 Beehive Functional Drink Factory

Spanning 50,000 square meters, the S16 facility is equipped with advanced high-speed automated production lines, enabling efficient delivery of a wide range of products to the US market. The S16 factory serves as a hub, integrating TCI's research and development capabilities from China, Taiwan, and the United States. This global collaboration allows us to offer 24/7 service to clients worldwide, supporting their efforts to expand their international presence.

QUALITY IS OUR LEGACY

Production Dosage Form

- Functional drink

Monthly Production Capacity

- Functional drink 50ml, 60ml - 10 million bottles

- Functional drink 750ml - 1.92 million bottles

Special Certification

- USDA Organic Certification

AI Quality Control

In alignment with our state-of-the-art automated production processes, TCI has made a significant investment in developing the cutting-edge Eagle Eye monitoring system. This advanced technology, featuring high-speed CCD (Charge-Coupled Device) sensors, enables real-time production safety inspections that exceed human visual capabilities. It identifies defects such as abnormal or deformed bottle caps, thread distortions, cracks, impurities, glass fragments, and performs ultrasonic liquid level assessments. The system automatically rejects non-compliant products and operates continuously, inspecting 16.7 bottles per second with an exceptional detection accuracy of 99.9%, ensuring reliable, around-the-clock quality control.

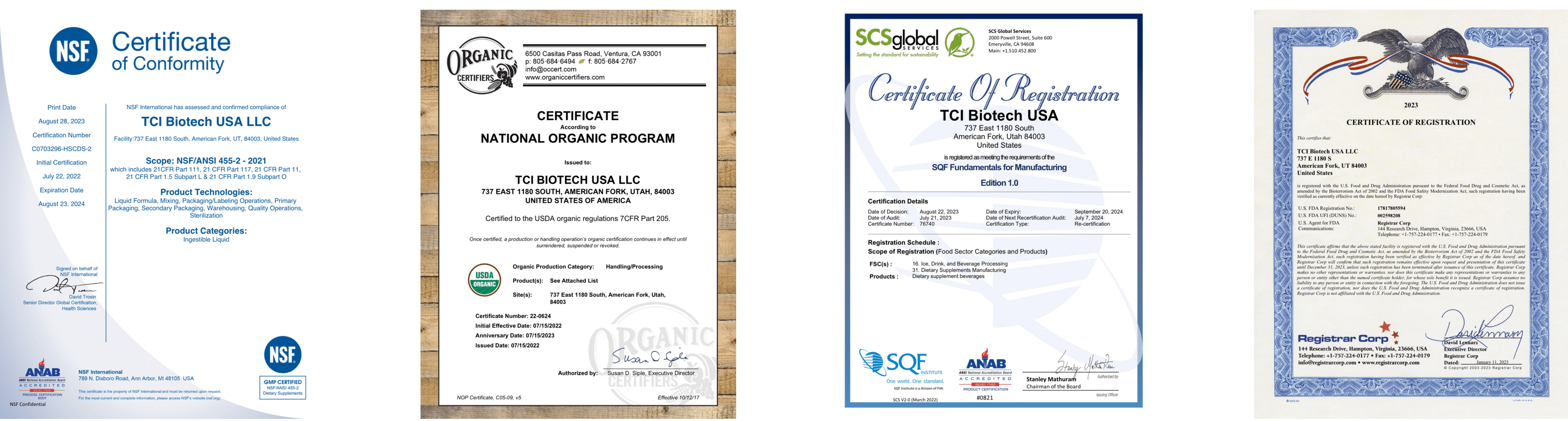

CERTIFICATIONS

GLOBAL TOTAL SOLUTION

We offer solutions across your product formulation development, analytical services and supply globally.